Changes are the daily bread of the developers. They are used throughout the entire product development process to achieve the goals of functional fulfilment, reliability and service life. In the case of large systems, changes also occur during use, e.g. because the original spare parts or modules are no longer available. In mechatronic systems, changes in the software are even more common than in the hardware. This applies again to product development as well as to the operation of the plants and fleets.

Each change has an intended purpose, in general increasing robustness against critical load conditions. As a rule, a change process is carried out to assess whether the intended effect will be achieved. The risk of changes to the changed function group is therefore relatively low. However, damage occurs from changes due to unwanted side effects – most often at other function groups.

The side effects can manifest themselves over longer effect chains on various function groups throughout a system. These risks are hardly manageable, because the entire network of effect chains in a system would have to be transparent. We therefore looked at this problem from below – from the damage mechanisms point of view. It turned out that we already have the ingredients for the required supervision – they are in the risk analysis, executed for the product validation.

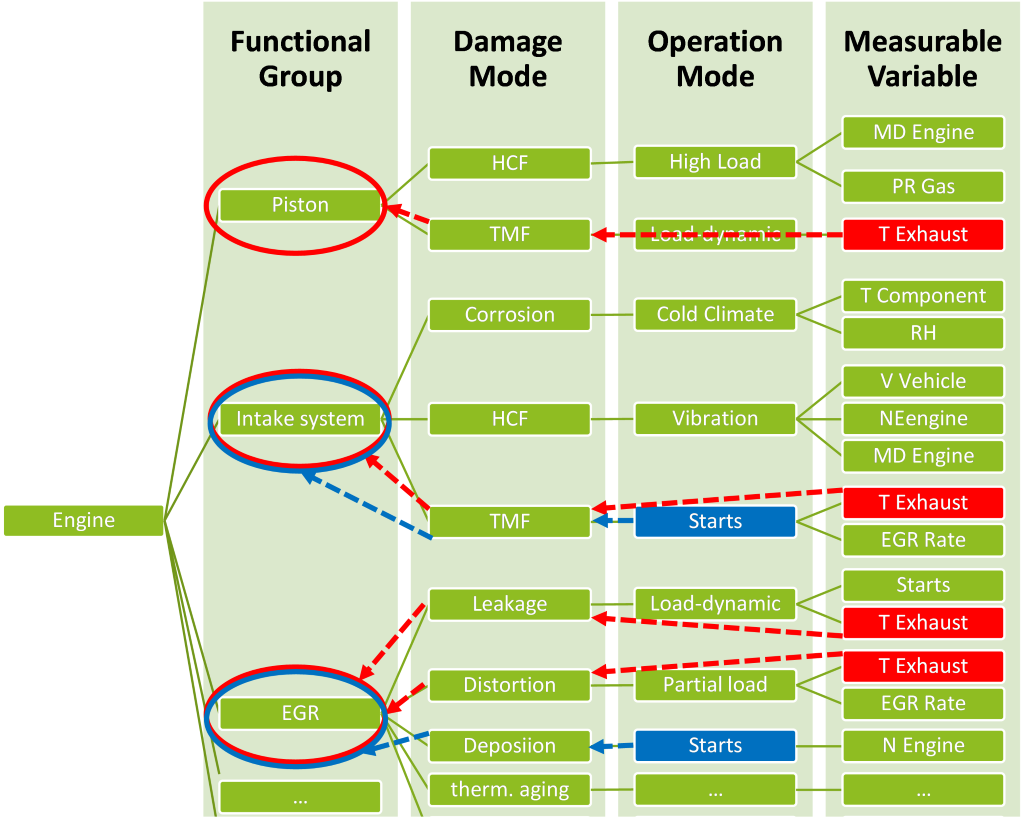

The figure shows an example of selected damage mechanisms of ICE function groups with their damaging operating modes and their relevant measured variables. If, for example the exhaust gas temperature of this machine has increased as a result of a manifold change, we expect an effect on all other components whose damage mechanisms are driven by the exhaust gas temperature: piston – thermal fatigue, inlet manifold – leakage, EGR system – distortion and so on. The list indicates where to take a closer look for mitigation of side effects.

For the identification of the side effects, it is even sufficient if only the operation modes, affected by a change are known, e.g., the software modification for hybrid starts affects EGR deposition and inlet manifold thermal fatigue.

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information