Reliability is a core product characteristic and is a continuous task over the entire life cycle. It demands cooperative risk management from the initial design phase, via functional development and validation, up to product maintenance. It involves overcoming numerous hurdles and information sinks. This can be achieved with a consistent reliability process over the entire product life cycle.

The challenges affecting the reliability of products and plant are manifold and different in nature. The organisational and technical interfaces resulting from processes that divide work into packages lead to a loss of information. The continuously increasing number of product variations is overwhelming risk elimination. High rates of innovation create mismatches between the structure of specialists and the requirements. In the case of mechatronic, controlled, or hybridised systems, this leads to unsatisfactory results.

The opponent of reliability is risk. A process radar is thus required that tracks all forms of risk drivers. Innovation, all manner of changes, and product variants play the main role here. Their undesired effects need to be determined and mitigated. This requires expert disciplines to collaborate according to the nature of the risk. And this can only be achieved with centralised process control.

Methods, tests, programs, models, and results are stored in such a manner that they remain available throughout the life cycle and also for future projects. This ensures that expert know-how is used efficiently.

The process focusses on the organisation and the holistic evaluation of the work-package activities. Development, manufacturing, quality, and maintenance are all integrated. The loss of knowledge at the organisational interfaces is avoided thanks to inter-disciplinary teams. They design reciprocal tasks and ensure the reuse of models and results. The Uptime SOLUTIONS software suite contains consistent methods to support the process.

The administration of product variants, the definition of functional groups, standard test programs, damage models, diagnostic algorithms, and lifetime models are defined unambiguously and only once. They provide a solid structure for a learning organisation.

The reliability process coordinates activities over the entire product life cycle.

It organises consistent workflows with clear responsibilities and interfaces. It standardises, documents, and provides consistent methods as well as result evaluation. This makes the distributed process plannable and controllable. The coupling of actors from all disciplines enables the emergence of sustainable synergies.

The process creates an organisation’s reliability memory.

Methods and generic results are derived from development projects and from operational experience and stored in the organisation’s knowledge base. This ensures high levels of quality over the entire reliability process and relieves the burden on experts for repetitive analyses.

The Uptime KNOWLEDGE base forms a cross-project platform for mutual learning regarding the topic of reliability.

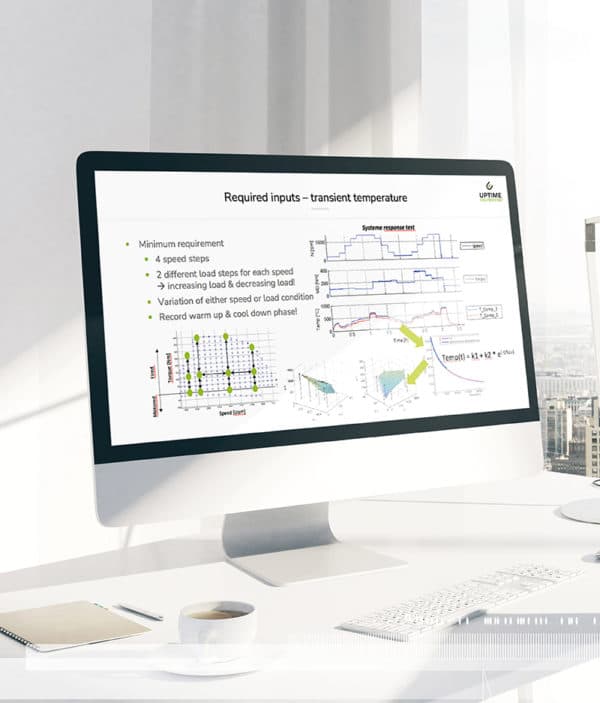

Physical modelling is diverse and pragmatic.

Test efficiency, risk coverage, and lifetimes are calculated using physical cause-effect models. They require only few input data, are transparent, and are known by engineers.

A compact and generic model library along with combination and configuration covers the enormous diversity of downtime risks in mechatronics. The adaptation in projects to special cases can be achieved quickly and without programming effort.

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information